Inteltek Automation provides unrivaled, advanced expertise for equipment & machine nationwide. We also provide solutions and products that are proven to provide more uptime, while enhancing your equipment with productivity, flexibility and rapid machine cycle times and increasing manufacturing throughput.

Inteltek's product ranges from motors to drives to PLC to motion controls to gearboxes to linear motion actuators- provides today's machines with the state-of-the-art solutions.

Our products are very easily and quickly installed, adjusted, integrated and maintained.

Inteltek's philosophy is to supply the best products available. The right combination of Inteltek's engineering expertise & the state-of-the-art products, result in more productivity, flexibility and less maintenance. By using our components, you can produce the high quality products.

Inteltek offers a wide range of Factory Automation Components like

- Servo Motors & Drives

- Micro Stepping Motors & Drives

- Miniature DC Motors & Drives

- Linear Motors & Drives

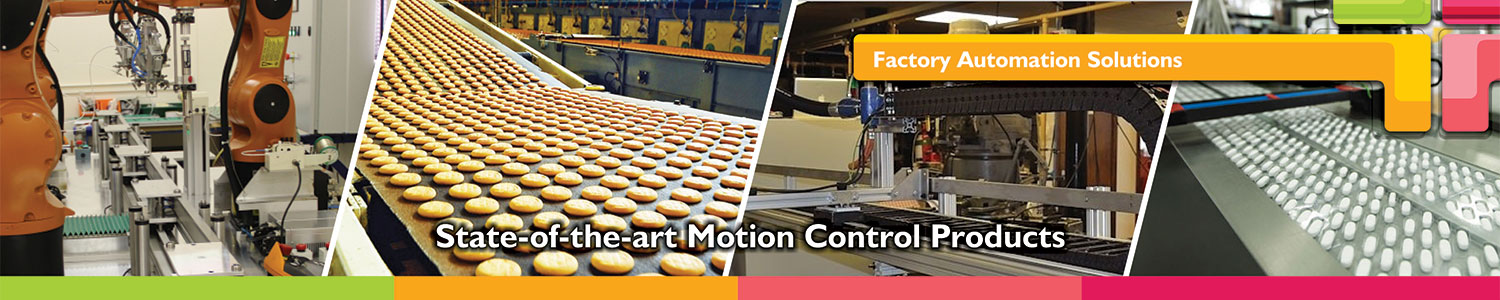

- PLC, Field Bus Components, SCADA

- Industrial PCs, Embedded PCs, HMI

- Motion Controls, Interfaces

- Safety Controls & Automation Products

- CNC Systems, DRO, Encoders

- Aluminum Profiles, Linear Guide ways, Couplings

- Servo Gearboxes

- Combined Bearings and Profiles

- Screw Jacks and Linear Actuators

You construct the mechanics of your system; we design and install the electronics control system, whether in-house or worldwide at your customer�s site.

Our interest is always in the successful operation of the overall system, and, naturally, its optimization through Factory Automation Products from our worldwide & renowned partners, our Application Engineering Expertise and Services.

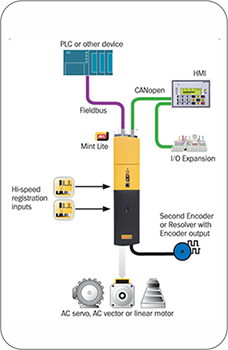

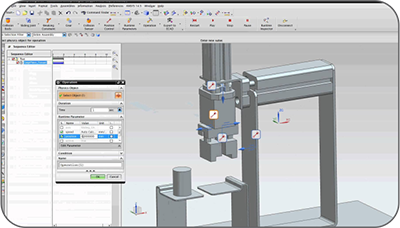

For this, we rely on continuous improvement in our know-how & capabilities. We develop customized solutions for automation needs using latest products & technology in the industry. Our solutions are implemented successfully in every branch of electro - mechanical engineering, from standard machines, special machines to mass-produced ones. We design, develop and supply complete automation systems, from factory automation component sales, control systems to the machine controller and software solutions to the electro-mechanical drive systems.

Supporting our customers, right from understanding requirement, finalizing the specifications, developing the concept, designing the system architecture, selecting appropriate system components, application software development, upto the successful commissioning of the system and service over the lifespan of the product is part of our company philosophy. As part of our comprehensive service spectrum, application engineering, technical support and allied services play a decisive role.

Technical competency, innovation, flexibility, quality engineering, competitiveness and total customer orientation are the characteristics of our company philosophy.

We have team of experienced & factory trained engineers (Electrical, Electronics, Mechanical & Software Engineering streams) for in-house development of Control Systems, user friendly GUI, Application Software and Special Purpose Machines.

Our team�s dedication & commitment lasts over the entire working relationship with our customers.... from concept to commissioning and maintenance.

Engineering Services

- Complete Automation Solutions

- Design & Development

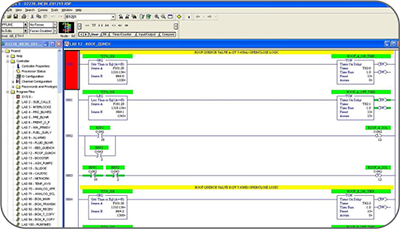

- Hardware & Software Engineering

- Control Panel Designing

- Control Systems Engineering & Integration

- Project Management

- Application Software Developments

- Development of Test & Simulation Systems

- Installation & Commissioning

- Technical Support & On-site Services

- Training & Seminars

- Repairs & Maintenance

- Retrofitting & Refurbishing of old CNC Machines

- Special Purpose Machine Building

One can source automation components from different catalogues and put them together. Sometime it appears to be a cheaper solution. This is fine for one-off & non critical requirements.

When it comes to building the high performance equipments, integrating machines into the mass production lines or dealing with export opportunities, one obviously expects optimized solutions that are highly reliable, meeting demanding requirements at the same time not overlooking cost aspect, the right solution tends to be a right selection of components which together provide the fitting package that would satisfy multiple criteria. This is where a customized solution makes a difference.

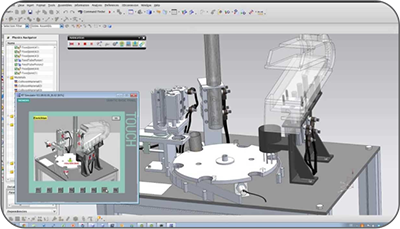

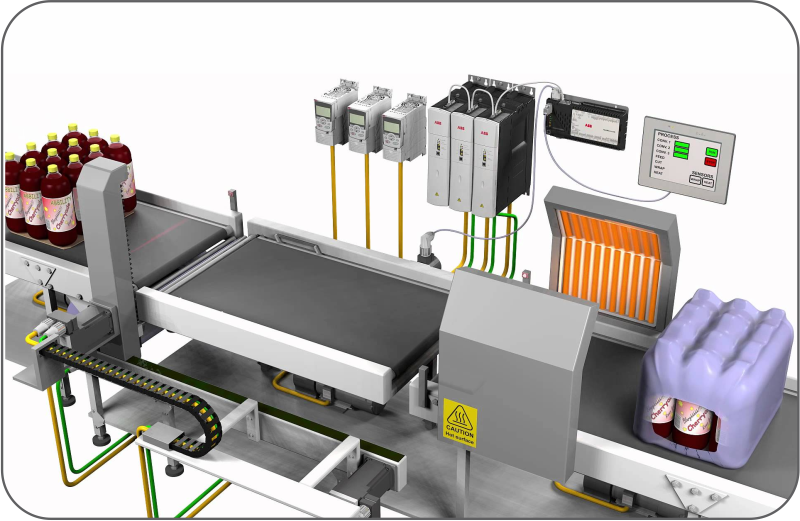

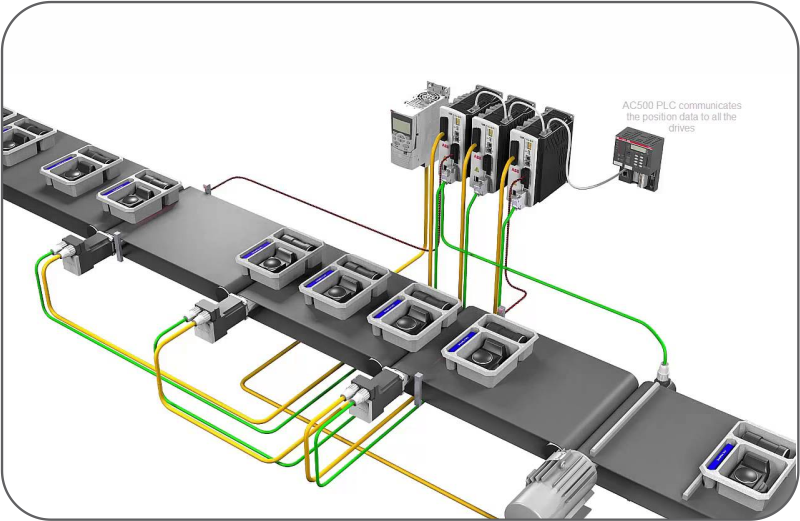

Our customized Servo-Motion Control solution uses standard Rotary & Linear Servo Motors and Drives, Integrated Micro-stepping Drives, Planetary Gearheads, Motion Controls, Industrial PCs, HMI, Encoders & Sensors etc. from renowned multinational suppliers.

We have team of experienced & factory trained engineers (Electrical, Electronics, Mechanical & Software Engineering streams) for in-house development of control systems, user friendly GUI, application software and Special Purpose Machines.

Over a period, we had opportunities to provide customized solutions for diversified applications and today we can proudly say that we have a footprint in very diverse fields for automation.

Customized Applications undertaken

- Indexing & Positioning

- Interpolation & Contouring

- Cut to length or In-feed Systems

- Flying Shears & Rotary Cutters

- Print on Registration Mark

- CAM Profiling

- Profile Cutting / Flame Cutting

- Glass Cutting & Grinding

- Electronic Cam / Electronic Gearing

- Multi-axes Synchronization

- Gantry Loaders

- Assembly Line Integration

Market Segments catered

- Automotive

- Printing & Packaging

- Pharmaceuticals

- Plastics processing

- Textile manufacturing and processing

- Food & Beverages processing

- Glass processing

- Profile Cutting / Flame Cutting

- Glass Cutting & Grinding

- Electronic Cam / Electronic Gearing

- Multi-axes Synchronization

- Gantry Loaders

- Assembly Line Integration

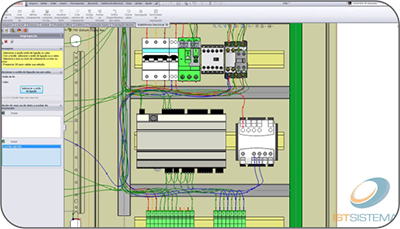

Control Panel Building

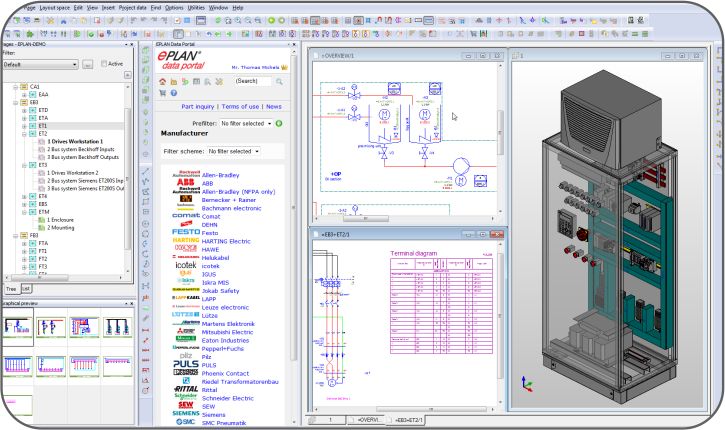

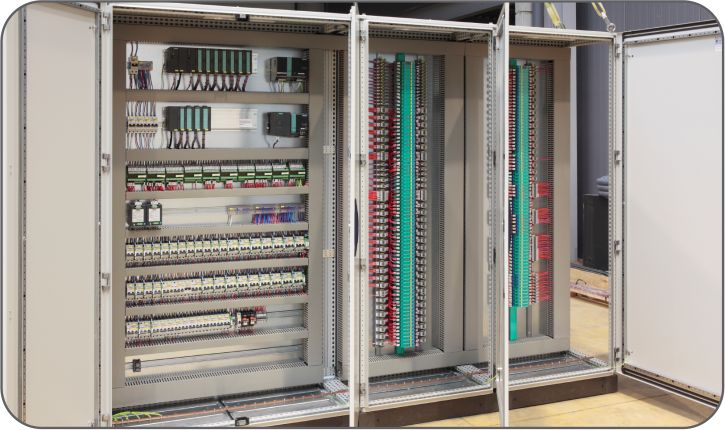

We do complete engineering of control panels for your machines using most latest and widely used IEC standards for low-voltage controls, switchgears, power supplies, cabling and distribution.

We use standard components from Siemens, ABB, Schneider Electric, TDK-EPCOS, Schaffner, Bussmann, GEC English Electric, Phoenix Mecano, Lappkabel, Helukabel and Rittal, etc. in the control panels built by us for export purpose.

We use ePlan Electric P8 software as a powerful tool for designing of control system, wiring diagrams, project planning, documentation and management of automation projects.

From the dimensioning via cabling to air conditioning of your control cabinets, we design your hardware taking account of all design and manufacturing options that are technologically innovative, user-oriented and as economical as possible.

Customer Support

Our customer support team for technical support, application development and training is available nationwide at all important industrial locations. Our support is available throughout the lifespan of the products. We also provide online support via emails, telephone, team-viewer, etc. We closely work with the design, development and manufacturing teams of our customers to continuously improve our systems or solutions based on their feedback.

Repairs Centre

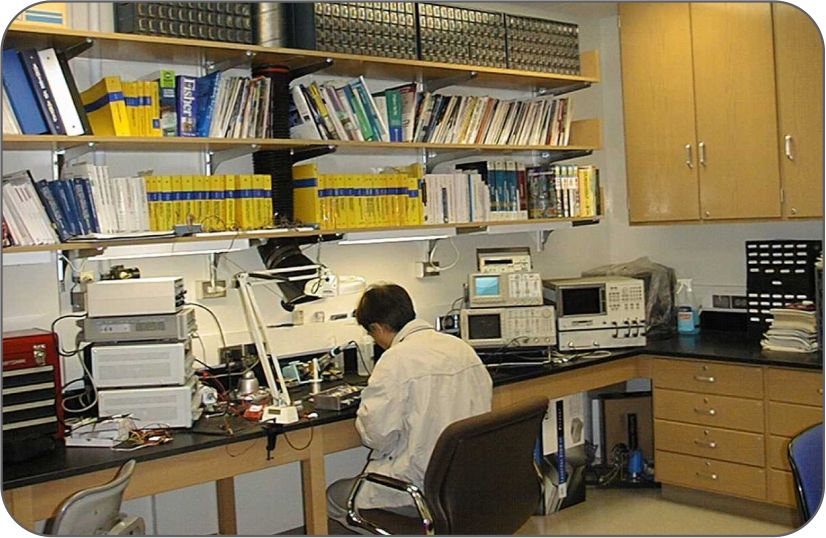

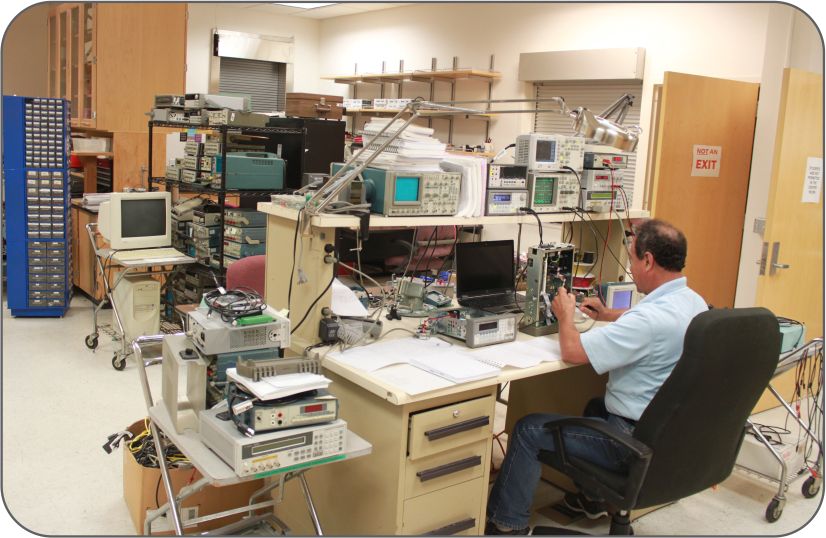

We are an established and professional Servo-Motion & CNC Controls Repair facility with extensive experience of repairing variety and makes of Servo Motors, Servo Drives, Motion Controls, AC Drives, Industrial Motors, CNC Controls & Feedback Devices, etc.

We undertake simple as well as complex repair jobs, on-board repairs and follow standard test procedures & specialized techniques. Our factory trained technicians ensures that your product is properly diagnosed, repaired, run-tested and aligned to the manufacturer�s specifications.

We have well equipped electronics lab, machine shop & associate motor repairs facility. We have maintained test equipments, special test jigs, spare parts & necessary engineering data about the products for which we undertake repairs.

Every customer expects the timely & correct repair support and spare parts availability during any system failure. We provide such emergency repair services. We also manage spare parts inventory in cooperation with our principals & customers.

We focus on providing reliability coupled with fast turn-around times, cost saving solutions and extraordinary customer service. This has earned INTELTEK preferred vendor status for Servo-Motion-CNC Controls repairs.

Our establishment has provided repairs & technical services for renowned Servo-Motion-CNC Controls manufactures like ABB, Baldor Electric, Beckhoff, DeltaTau, Fuji Electric, Mavilor, Infranor, Motrona, Schneider Electric, Reliance Electric, Fagor, Fanuc, Siemens, Mitsubishi Electric, NUM & for many Machine Builders in India.

INTELTEK is authorized repair facility for ABB � Baldor Electric, Fuji Electric, Mavilor � Infranor, Fagor Automation & NUM.

We also undertake Annual Maintenance Contracts & On-site Support requirements for our customers through our nationwide operation network.

We are currently seeking the partners to use our expertise, know-how & services and to set up joint ventures in the interest of expanding internationally. We also wish to provide Sales & Marketing, System Integration, Value Added Services in India for various international companies that manufacture factory automation products and having worldwide customer base.